Develop new products based on customer and market needs.

Ensure high-quality low lead material selection through spectroscopy, and undergo high-tech low lead treatment to ensure that the product does not form secondary pollution.

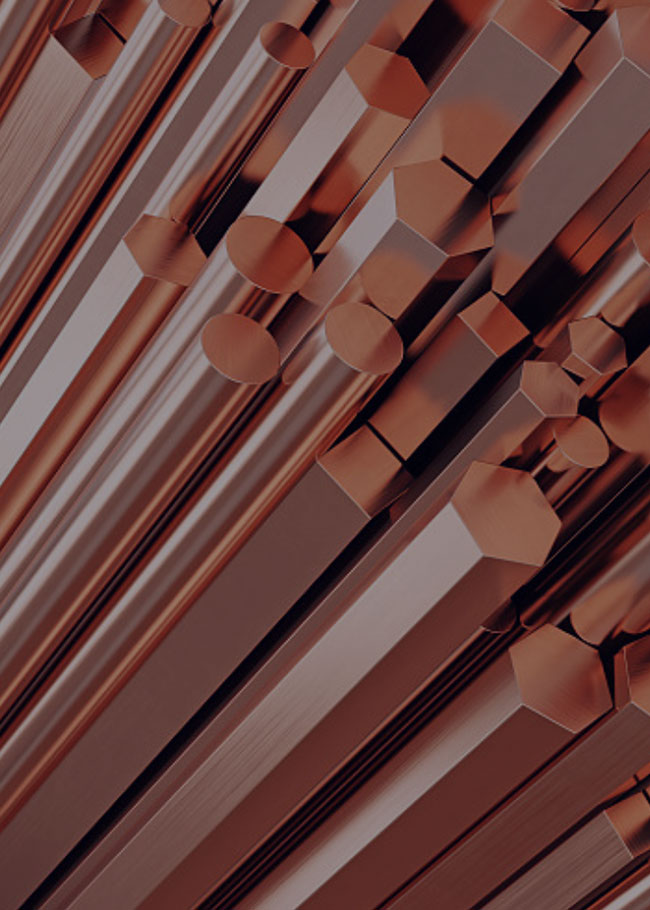

High tonnage hot forging technology makes the product surface appear flat, smooth, smooth, and even.

Automatic assembly line production, high efficiency, ensuring sufficient supply of goods.

By using high-precision CNC machine tools and multi-station specialized machines, the blank is processed into high-precision spare parts.

All blanks undergo tempering treatment to increase product toughness and prolong product service life.

Testing the tensile, torsional, bending, flow rate of the product itself, as well as the lifespan and high and low temperature testing of component valve cores, hoses, etc.

Product classification and warehousing, timely shipment according to orders